Your Blog

Included page "clone:mamiealcorn37760" does not exist (create it now)

The basic knowledge that the brick making machine should master in the production process - 08 Aug 2018 08:44

Tags:

brick making machine in india machine technology can be said to be and the quality of the product has a direct link, with more and more areas, construction projects need to apply to different specifications, material bricks, so that the brick machine in the production process should grasp the basic knowledge has become the focus of attention information.Now let's listen to what the pros are explaining.Basic common sense of brick making machine the first, a new generation of brick machine can be said to be the product of the High-tech era, can use a lot of raw materials, including some can not be processed and can not recycle the garbage, absolutely meet the 21st century environmental protection and energy conservation concept.Second, although belonging to High-tech equipment, but in the course of operation, there are still some security risks, so the relevant operators must follow the prescribed procedures for the operation, can not adjust the operating procedures.Third, the brick making machine technology in the operation of the operation process, attaches great importance to the field work environment in the temperature, humidity and other factors, especially the temperature or brick machine thermal control does not meet the standards, may lead to a variety of fires, equipment failures, and other problems, resulting in different degrees of accidents.  Four, usually such brick machine equipment must establish a sound management system, and each post has a special person to carry out, we need to seriously adhere to their posts.Five, because the current brick making machine can produce different kinds of bricks, the choice of raw materials is also different, before each boot should carefully understand the relevant standards of today's operations, such as the type of bricks, size and specifications, thickness and other performance parameters.Six, before making production, must be the corresponding design of bricks, because only the size of the bricks, structure and other reasonable design, construction is more convenient.Seven, staff in the process of making brick machine process, such as wearing a good professional protective tools, such as masks, professional glasses and so on, so as to avoid their own body suffered from various accidental attacks.The advent of the High-tech era, so that more and more high-tech equipment has become an auxiliary helper in all walks of life, and the use of brick machine, only in accordance with the right brick machine process process to carry out, can provide users with more high-quality bricks, to ensure the progress of the construction at the same time, can improve the qualityWant to know more about the production of this type of equipment information, you are welcome to keep an eye on our website update dynamic. - Comments: 0

Four, usually such brick machine equipment must establish a sound management system, and each post has a special person to carry out, we need to seriously adhere to their posts.Five, because the current brick making machine can produce different kinds of bricks, the choice of raw materials is also different, before each boot should carefully understand the relevant standards of today's operations, such as the type of bricks, size and specifications, thickness and other performance parameters.Six, before making production, must be the corresponding design of bricks, because only the size of the bricks, structure and other reasonable design, construction is more convenient.Seven, staff in the process of making brick machine process, such as wearing a good professional protective tools, such as masks, professional glasses and so on, so as to avoid their own body suffered from various accidental attacks.The advent of the High-tech era, so that more and more high-tech equipment has become an auxiliary helper in all walks of life, and the use of brick machine, only in accordance with the right brick machine process process to carry out, can provide users with more high-quality bricks, to ensure the progress of the construction at the same time, can improve the qualityWant to know more about the production of this type of equipment information, you are welcome to keep an eye on our website update dynamic. - Comments: 0

Four, usually such brick machine equipment must establish a sound management system, and each post has a special person to carry out, we need to seriously adhere to their posts.Five, because the current brick making machine can produce different kinds of bricks, the choice of raw materials is also different, before each boot should carefully understand the relevant standards of today's operations, such as the type of bricks, size and specifications, thickness and other performance parameters.Six, before making production, must be the corresponding design of bricks, because only the size of the bricks, structure and other reasonable design, construction is more convenient.Seven, staff in the process of making brick machine process, such as wearing a good professional protective tools, such as masks, professional glasses and so on, so as to avoid their own body suffered from various accidental attacks.The advent of the High-tech era, so that more and more high-tech equipment has become an auxiliary helper in all walks of life, and the use of brick machine, only in accordance with the right brick machine process process to carry out, can provide users with more high-quality bricks, to ensure the progress of the construction at the same time, can improve the qualityWant to know more about the production of this type of equipment information, you are welcome to keep an eye on our website update dynamic. - Comments: 0

Four, usually such brick machine equipment must establish a sound management system, and each post has a special person to carry out, we need to seriously adhere to their posts.Five, because the current brick making machine can produce different kinds of bricks, the choice of raw materials is also different, before each boot should carefully understand the relevant standards of today's operations, such as the type of bricks, size and specifications, thickness and other performance parameters.Six, before making production, must be the corresponding design of bricks, because only the size of the bricks, structure and other reasonable design, construction is more convenient.Seven, staff in the process of making brick machine process, such as wearing a good professional protective tools, such as masks, professional glasses and so on, so as to avoid their own body suffered from various accidental attacks.The advent of the High-tech era, so that more and more high-tech equipment has become an auxiliary helper in all walks of life, and the use of brick machine, only in accordance with the right brick machine process process to carry out, can provide users with more high-quality bricks, to ensure the progress of the construction at the same time, can improve the qualityWant to know more about the production of this type of equipment information, you are welcome to keep an eye on our website update dynamic. - Comments: 0How to buy multifunctional brick making machine? - 06 Aug 2018 08:41

Tags:

With the gradual upgrading of infrastructure and the growing demand for bricks, our producers ' demand for brick making machines has been increasing.Then in a variety of production needs, everyone in the use of the purchase of equipment in the process will be a question, that is how to buy multi-functional brick machine? Multi-function brick making machine price how to wait for this problem, Lontto machine and everyone come to chat.To buy multi-functional brick machine, you need to choose the right equipment for their own needs, the use of their own reasonable positioning, including what type of bricks they produce, and the expected output is how much, as well as the production of bricks are used in where and so on? These are in the purchase of multi-functional brick making machine needs attention to the positioning of the details of the factors.We generally use the red bricks and tiles and so are the more common bricks, these bricks whether in strength or in the internal sealing control are more stringent requirements, that is, from the beginning of the selection of materials, the corresponding multi-functional brick machine can have more straightforward changes, So in the purchase of the time must pay attention to the internal machine is not a corresponding handsome selection system, more suitable materials to effectively help the performance of bricks to achieve.Next is the output of the equipment, from many new multi-functional brick machine analysis, equipment production in the design process has been effective promotion, including equipment processing more familiar with the process, can effectively complete the equipment step between the interface, to help the equipment better finish the corresponding processing, There are a lot of devices in the production process will even use computer programming to help organize the connection between the equipment.Multi-function brick making machine price is also a matter of concern when you buy, for users, economic budget is also an important factor affecting the production of equipment.The general multi-function brick machine price and equipment performance, as well as the choice of business has a great relationship.In short, the purchase of multi-functional cement brick machine when there are many factors to consider, from the multi-functional brick making machine price and performance analysis is the case.Of course, choose the right provider is also indispensable, I believe lontto machine because of unique performance and market experience is the ideal choice for many users, welcome interested customers to choose us.  - Comments: 0

- Comments: 0

- Comments: 0

- Comments: 0Factors affecting the price of brick making machine and the main points of maintenance and. - 04 Aug 2018 03:46

Tags:

Now we can find in the market many different manufacturers to launch the Brick machine, in the price is high and low.Here we will listen to the basic introduction of the professional, to see the impact of the price of brick making machine and maintenance points in the end what is it? brick making machine price list machine price factors first, the different equipment brands, China's brick making machine brand there are many, each manufacturer introduced equipment quality, performance and price are a big difference.Because the manufacturers of different brands in the use of production equipment, production technology and raw materials, and so on, are a certain difference, it is recommended that you choose well-known enterprises, so that more effectively ensure the performance of such equipment and quality.Second, the model is different, now the same manufacturer launched the brick machine model has many, each model of equipment has its own advantages and characteristics.In addition, there are differences in the steps and prices of each model.  Third, the service is different, now in the purchase of such equipment, different consumers also choose the same service, some package distribution transport, some package installation and maintenance, and so on, because the different service content, it will also lead to the price of such equipment there is a high or low difference.The main points of maintenance of brick making machine first, many manufacturers in the use of such equipment, there is no maintenance of a concept, often equipment failure to repair the problem, in fact, this concept is not correct.It should be based on the frequency of use of such equipment, so as to develop a sound maintenance program.Second, the operation of such equipment, must be in accordance with the correct procedures, and after each maintenance, should be used to record the appropriate text.Third, any machinery and equipment should be clean, fastening, lubrication and adjustment measures, so as to better ensure that the performance of the brick machine will not have problems, but also can effectively extend the service life of the equipment.Four, because the operation of a long time, it is likely to bring different loss of equipment, this time if the discovery of parts or other structural damage, need to be replaced, you must choose the original manufacturers of parts, and pay attention to models, specifications are not in line with the needs of brick machine equipment. - Comments: 0

Third, the service is different, now in the purchase of such equipment, different consumers also choose the same service, some package distribution transport, some package installation and maintenance, and so on, because the different service content, it will also lead to the price of such equipment there is a high or low difference.The main points of maintenance of brick making machine first, many manufacturers in the use of such equipment, there is no maintenance of a concept, often equipment failure to repair the problem, in fact, this concept is not correct.It should be based on the frequency of use of such equipment, so as to develop a sound maintenance program.Second, the operation of such equipment, must be in accordance with the correct procedures, and after each maintenance, should be used to record the appropriate text.Third, any machinery and equipment should be clean, fastening, lubrication and adjustment measures, so as to better ensure that the performance of the brick machine will not have problems, but also can effectively extend the service life of the equipment.Four, because the operation of a long time, it is likely to bring different loss of equipment, this time if the discovery of parts or other structural damage, need to be replaced, you must choose the original manufacturers of parts, and pay attention to models, specifications are not in line with the needs of brick machine equipment. - Comments: 0

Third, the service is different, now in the purchase of such equipment, different consumers also choose the same service, some package distribution transport, some package installation and maintenance, and so on, because the different service content, it will also lead to the price of such equipment there is a high or low difference.The main points of maintenance of brick making machine first, many manufacturers in the use of such equipment, there is no maintenance of a concept, often equipment failure to repair the problem, in fact, this concept is not correct.It should be based on the frequency of use of such equipment, so as to develop a sound maintenance program.Second, the operation of such equipment, must be in accordance with the correct procedures, and after each maintenance, should be used to record the appropriate text.Third, any machinery and equipment should be clean, fastening, lubrication and adjustment measures, so as to better ensure that the performance of the brick machine will not have problems, but also can effectively extend the service life of the equipment.Four, because the operation of a long time, it is likely to bring different loss of equipment, this time if the discovery of parts or other structural damage, need to be replaced, you must choose the original manufacturers of parts, and pay attention to models, specifications are not in line with the needs of brick machine equipment. - Comments: 0

Third, the service is different, now in the purchase of such equipment, different consumers also choose the same service, some package distribution transport, some package installation and maintenance, and so on, because the different service content, it will also lead to the price of such equipment there is a high or low difference.The main points of maintenance of brick making machine first, many manufacturers in the use of such equipment, there is no maintenance of a concept, often equipment failure to repair the problem, in fact, this concept is not correct.It should be based on the frequency of use of such equipment, so as to develop a sound maintenance program.Second, the operation of such equipment, must be in accordance with the correct procedures, and after each maintenance, should be used to record the appropriate text.Third, any machinery and equipment should be clean, fastening, lubrication and adjustment measures, so as to better ensure that the performance of the brick machine will not have problems, but also can effectively extend the service life of the equipment.Four, because the operation of a long time, it is likely to bring different loss of equipment, this time if the discovery of parts or other structural damage, need to be replaced, you must choose the original manufacturers of parts, and pay attention to models, specifications are not in line with the needs of brick machine equipment. - Comments: 0How to choose color paving brick machinery and equipment specific characteristics of what - 03 Aug 2018 03:41

Tags:

When we build a house, we need to use bricks, and bricks are made of colored paving brick machines.The color paving brick machine equipment has the height and the density, the double control function.and the corresponding small size, greater pressure, more simple operation, maintenance more convenient, more reliable operation and other advantages.Very economical and technologically advanced.Color paving brick machine equipment can not only produce color road tiles, but also the production of color tiles, bread bricks and standard bricks.The corresponding types of more, according to the production of brick-type, can be divided into hydraulic, road and other types of roads.Therefore for the vast number of consumers, in the brick machine to buy, should be comprehensive consideration, to ensure that the choice of suitable equipment, the greatest degree to meet their own needs.Of course, in the daily use of the process, in order to be the corresponding function, better play out, at this time need to be clear color paving brick machine equipment characteristics.Its production capacity is strong, but also produces the brick, the strength is very high, the water permeability is strong.Will not skid, to meet environmental needs of High-tech products.  At the same time, the corresponding color is very rich, the specification is very complete, more beautiful, very simple.Equipment can produce various models of color bricks, slope protection brick and so on.Laying on both sides of the road, you can enhance the water permeability, environmental protection, you can beautify the environment.Clear the color paving brick machine equipment characteristic, the daily use process, but also needs to have the concrete operation maintenance skill to have the mastery.In the use of new color paving brick machinery and equipment, should be the total pressure regulator, adjust to the motor can not be suffocated, at the same time can not be too much difficulty.Should be the cycle, put to the bottom of the concave die, open the motor, the lower pressure mode joystick, should observe the damping block making machine of the lower pressure level.In the operation of the time, you should control the specific pressure.If it is counterclockwise operation, you need to specify the specific pressure range.When debugging a brick, if found that the vibration force is insufficient, should check the upper pressure topped cylinder, whether there is excessive pressure.If it appears too high, should be counterclockwise adjustment, when the brick strength is good, then should be appropriate callback.Of course, at this time, we should also calculate the specific loss rate, the greatest degree to reduce losses.Finally, we need to be clear about the specific technical parameters.Only to the parameters, and color paving brick machine equipment characteristics to understand the situation, can be more effective to play out, to the greatest extent to meet the needs of the enterprise equipment. - Comments: 0

At the same time, the corresponding color is very rich, the specification is very complete, more beautiful, very simple.Equipment can produce various models of color bricks, slope protection brick and so on.Laying on both sides of the road, you can enhance the water permeability, environmental protection, you can beautify the environment.Clear the color paving brick machine equipment characteristic, the daily use process, but also needs to have the concrete operation maintenance skill to have the mastery.In the use of new color paving brick machinery and equipment, should be the total pressure regulator, adjust to the motor can not be suffocated, at the same time can not be too much difficulty.Should be the cycle, put to the bottom of the concave die, open the motor, the lower pressure mode joystick, should observe the damping block making machine of the lower pressure level.In the operation of the time, you should control the specific pressure.If it is counterclockwise operation, you need to specify the specific pressure range.When debugging a brick, if found that the vibration force is insufficient, should check the upper pressure topped cylinder, whether there is excessive pressure.If it appears too high, should be counterclockwise adjustment, when the brick strength is good, then should be appropriate callback.Of course, at this time, we should also calculate the specific loss rate, the greatest degree to reduce losses.Finally, we need to be clear about the specific technical parameters.Only to the parameters, and color paving brick machine equipment characteristics to understand the situation, can be more effective to play out, to the greatest extent to meet the needs of the enterprise equipment. - Comments: 0

At the same time, the corresponding color is very rich, the specification is very complete, more beautiful, very simple.Equipment can produce various models of color bricks, slope protection brick and so on.Laying on both sides of the road, you can enhance the water permeability, environmental protection, you can beautify the environment.Clear the color paving brick machine equipment characteristic, the daily use process, but also needs to have the concrete operation maintenance skill to have the mastery.In the use of new color paving brick machinery and equipment, should be the total pressure regulator, adjust to the motor can not be suffocated, at the same time can not be too much difficulty.Should be the cycle, put to the bottom of the concave die, open the motor, the lower pressure mode joystick, should observe the damping block making machine of the lower pressure level.In the operation of the time, you should control the specific pressure.If it is counterclockwise operation, you need to specify the specific pressure range.When debugging a brick, if found that the vibration force is insufficient, should check the upper pressure topped cylinder, whether there is excessive pressure.If it appears too high, should be counterclockwise adjustment, when the brick strength is good, then should be appropriate callback.Of course, at this time, we should also calculate the specific loss rate, the greatest degree to reduce losses.Finally, we need to be clear about the specific technical parameters.Only to the parameters, and color paving brick machine equipment characteristics to understand the situation, can be more effective to play out, to the greatest extent to meet the needs of the enterprise equipment. - Comments: 0

At the same time, the corresponding color is very rich, the specification is very complete, more beautiful, very simple.Equipment can produce various models of color bricks, slope protection brick and so on.Laying on both sides of the road, you can enhance the water permeability, environmental protection, you can beautify the environment.Clear the color paving brick machine equipment characteristic, the daily use process, but also needs to have the concrete operation maintenance skill to have the mastery.In the use of new color paving brick machinery and equipment, should be the total pressure regulator, adjust to the motor can not be suffocated, at the same time can not be too much difficulty.Should be the cycle, put to the bottom of the concave die, open the motor, the lower pressure mode joystick, should observe the damping block making machine of the lower pressure level.In the operation of the time, you should control the specific pressure.If it is counterclockwise operation, you need to specify the specific pressure range.When debugging a brick, if found that the vibration force is insufficient, should check the upper pressure topped cylinder, whether there is excessive pressure.If it appears too high, should be counterclockwise adjustment, when the brick strength is good, then should be appropriate callback.Of course, at this time, we should also calculate the specific loss rate, the greatest degree to reduce losses.Finally, we need to be clear about the specific technical parameters.Only to the parameters, and color paving brick machine equipment characteristics to understand the situation, can be more effective to play out, to the greatest extent to meet the needs of the enterprise equipment. - Comments: 0Various dimensions and construction code of aerated concrete block - 02 Aug 2018 03:35

Tags:

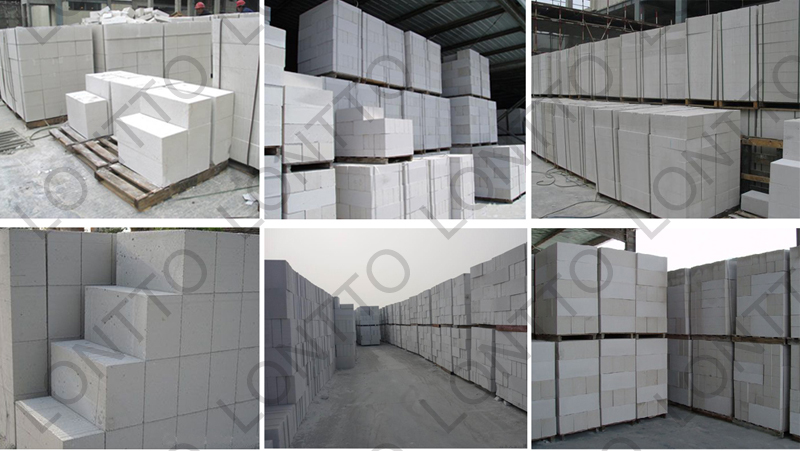

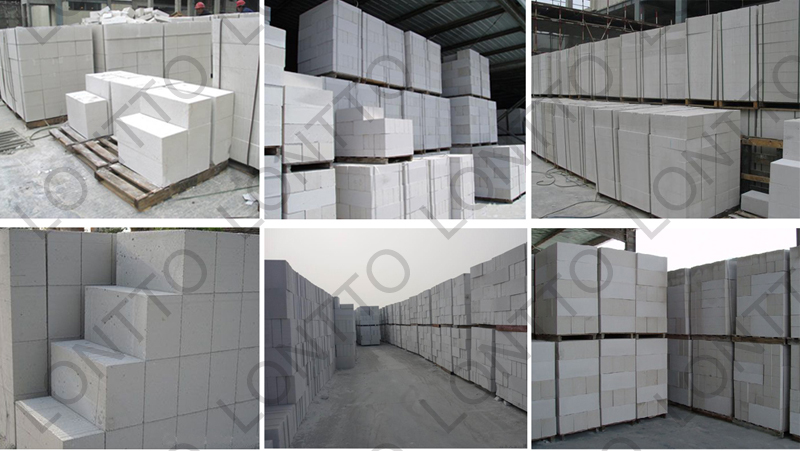

At present, the building materials market some materials prices have risen a lot, but really worthy of such a high price of material is not much.  Many friends may just contact the building materials this line, some circumstances do not understand, today let Lontto machine machinery I introduce some about aerated concrete block related knowledge.As the measurement method is different, the specifications of aerated concrete block are various.There are basically 5 kinds, if the height is 600*240*75mm, according to the square or the cubic is 13.33, according to the unit is block/square, then 6.9, according to the unit is cubic/Block making Machine, then 0.0108; according to block/cubic, then 92.59.We can simply refer to, and specifically to see the aerated concrete block manufacturers to provide products.In the production process of aerated concrete block, the corresponding construction code needs to be complied with.First, look at the surrounding facilities and equipment, the treatment of the treatment is good; second, pay attention to the aerated concrete block equipment in the boot, whether the insulation and grounding work, the Belt Road Wheel protection cover is complete; third, aerated concrete block equipment in the start-up, the first to idle for a period of time, to check the rotation direction of the mixing leaf is correct, can side feeding, Add water, side to stir work; four, do the mixer inside and outside the cleaning work, timely maintenance of good venues.In general, every production process should not be overlooked.As for the construction process of aerated concrete block, first of all, we should pay attention to the strength of the block should not be below the minimum standard, mortar strength should not be below the minimum standard.In the upper and lower skin blocks of aerated concrete block wall, the vertical gray seam should be staggered, and the length should be 150mm-300mm for each other.If unable to meet the requirements, should be in the horizontal gray seam set 2蠁6 tensile tendons or 蠁 4 mesh bar, length can not be less than 700mm.We all know very well that the safety of building construction is very important, in the use of aerated concrete block equipment, the need for careful operation, bearing in mind the operation and construction norms, so as to avoid irreparable accidents.Want to know more about this knowledge, we can pay close attention to the Lontto machine website, we will be the industry's firsthand information to share. - Comments: 0

Many friends may just contact the building materials this line, some circumstances do not understand, today let Lontto machine machinery I introduce some about aerated concrete block related knowledge.As the measurement method is different, the specifications of aerated concrete block are various.There are basically 5 kinds, if the height is 600*240*75mm, according to the square or the cubic is 13.33, according to the unit is block/square, then 6.9, according to the unit is cubic/Block making Machine, then 0.0108; according to block/cubic, then 92.59.We can simply refer to, and specifically to see the aerated concrete block manufacturers to provide products.In the production process of aerated concrete block, the corresponding construction code needs to be complied with.First, look at the surrounding facilities and equipment, the treatment of the treatment is good; second, pay attention to the aerated concrete block equipment in the boot, whether the insulation and grounding work, the Belt Road Wheel protection cover is complete; third, aerated concrete block equipment in the start-up, the first to idle for a period of time, to check the rotation direction of the mixing leaf is correct, can side feeding, Add water, side to stir work; four, do the mixer inside and outside the cleaning work, timely maintenance of good venues.In general, every production process should not be overlooked.As for the construction process of aerated concrete block, first of all, we should pay attention to the strength of the block should not be below the minimum standard, mortar strength should not be below the minimum standard.In the upper and lower skin blocks of aerated concrete block wall, the vertical gray seam should be staggered, and the length should be 150mm-300mm for each other.If unable to meet the requirements, should be in the horizontal gray seam set 2蠁6 tensile tendons or 蠁 4 mesh bar, length can not be less than 700mm.We all know very well that the safety of building construction is very important, in the use of aerated concrete block equipment, the need for careful operation, bearing in mind the operation and construction norms, so as to avoid irreparable accidents.Want to know more about this knowledge, we can pay close attention to the Lontto machine website, we will be the industry's firsthand information to share. - Comments: 0

Many friends may just contact the building materials this line, some circumstances do not understand, today let Lontto machine machinery I introduce some about aerated concrete block related knowledge.As the measurement method is different, the specifications of aerated concrete block are various.There are basically 5 kinds, if the height is 600*240*75mm, according to the square or the cubic is 13.33, according to the unit is block/square, then 6.9, according to the unit is cubic/Block making Machine, then 0.0108; according to block/cubic, then 92.59.We can simply refer to, and specifically to see the aerated concrete block manufacturers to provide products.In the production process of aerated concrete block, the corresponding construction code needs to be complied with.First, look at the surrounding facilities and equipment, the treatment of the treatment is good; second, pay attention to the aerated concrete block equipment in the boot, whether the insulation and grounding work, the Belt Road Wheel protection cover is complete; third, aerated concrete block equipment in the start-up, the first to idle for a period of time, to check the rotation direction of the mixing leaf is correct, can side feeding, Add water, side to stir work; four, do the mixer inside and outside the cleaning work, timely maintenance of good venues.In general, every production process should not be overlooked.As for the construction process of aerated concrete block, first of all, we should pay attention to the strength of the block should not be below the minimum standard, mortar strength should not be below the minimum standard.In the upper and lower skin blocks of aerated concrete block wall, the vertical gray seam should be staggered, and the length should be 150mm-300mm for each other.If unable to meet the requirements, should be in the horizontal gray seam set 2蠁6 tensile tendons or 蠁 4 mesh bar, length can not be less than 700mm.We all know very well that the safety of building construction is very important, in the use of aerated concrete block equipment, the need for careful operation, bearing in mind the operation and construction norms, so as to avoid irreparable accidents.Want to know more about this knowledge, we can pay close attention to the Lontto machine website, we will be the industry's firsthand information to share. - Comments: 0

Many friends may just contact the building materials this line, some circumstances do not understand, today let Lontto machine machinery I introduce some about aerated concrete block related knowledge.As the measurement method is different, the specifications of aerated concrete block are various.There are basically 5 kinds, if the height is 600*240*75mm, according to the square or the cubic is 13.33, according to the unit is block/square, then 6.9, according to the unit is cubic/Block making Machine, then 0.0108; according to block/cubic, then 92.59.We can simply refer to, and specifically to see the aerated concrete block manufacturers to provide products.In the production process of aerated concrete block, the corresponding construction code needs to be complied with.First, look at the surrounding facilities and equipment, the treatment of the treatment is good; second, pay attention to the aerated concrete block equipment in the boot, whether the insulation and grounding work, the Belt Road Wheel protection cover is complete; third, aerated concrete block equipment in the start-up, the first to idle for a period of time, to check the rotation direction of the mixing leaf is correct, can side feeding, Add water, side to stir work; four, do the mixer inside and outside the cleaning work, timely maintenance of good venues.In general, every production process should not be overlooked.As for the construction process of aerated concrete block, first of all, we should pay attention to the strength of the block should not be below the minimum standard, mortar strength should not be below the minimum standard.In the upper and lower skin blocks of aerated concrete block wall, the vertical gray seam should be staggered, and the length should be 150mm-300mm for each other.If unable to meet the requirements, should be in the horizontal gray seam set 2蠁6 tensile tendons or 蠁 4 mesh bar, length can not be less than 700mm.We all know very well that the safety of building construction is very important, in the use of aerated concrete block equipment, the need for careful operation, bearing in mind the operation and construction norms, so as to avoid irreparable accidents.Want to know more about this knowledge, we can pay close attention to the Lontto machine website, we will be the industry's firsthand information to share. - Comments: 0What are the advantages of the brick making machine equipment? - 27 Jul 2018 07:17

Tags:

Now we can choose a lot of useful and durable equipment to use, so that people's production efficiency has improved a lot.One of the brick making machine equipment is a kind of more attention to the product, in many places in the field has a key application.What are the characteristics of the brick making machine? This is a matter of concern to all of us, the following experts to do for everyone to carry out the advantages of brick making equipment.The reason why the equipment of brick making machine is favored by people is that it has many advantages.First of all, the brick making machine in the operation of the use of is extremely simple, users can in a relatively short period of time to master the operation of equipment.So the enterprise does not need to spend a lot of money to carry on the training of personnel, and can operate in a short time, can shorten the training time greatly.Secondly, the brick making machine has the advantages of low noise, safe and reliable operation, so that people can be assured to choose.We know that the noise of construction equipment, not only affect the lives of the people around, but also to the operators have a certain impact, and noise is small, can reduce the damage as much as possible.Third, the brick block making machine machine has the characteristic of high efficiency and energy saving, can save a lot of operation cost to the user, so the enterprise can save a lot of funds to use in other projects inside, better carry on the production.Four, the brick machine has the reasonable design, the craft reliable merit performance, in the service life performance is also extremely outstanding.Long-time use of this equipment will not be a failure, maintenance costs are cheap, not often to replace the equipment, save money.  The brick making machine has the characteristics of strong bearing capacity and high production efficiency, can produce high strength, and can finish the production task in a short time, so the enterprise can produce more products and get better benefits.From the above content can be seen brick machine equipment is a pretty good industrial products, can bring people a lot of benefits.and Lontto Machine Machinery Manufacturing Co., Ltd. is a strong strength of the professional production enterprises, in the industry played a leading position, to the vast number of customers to bring superior quality of the brick machine equipment products.The need for a friend to focus on their attention and careful inspection, will not let everyone down. - Comments: 0

The brick making machine has the characteristics of strong bearing capacity and high production efficiency, can produce high strength, and can finish the production task in a short time, so the enterprise can produce more products and get better benefits.From the above content can be seen brick machine equipment is a pretty good industrial products, can bring people a lot of benefits.and Lontto Machine Machinery Manufacturing Co., Ltd. is a strong strength of the professional production enterprises, in the industry played a leading position, to the vast number of customers to bring superior quality of the brick machine equipment products.The need for a friend to focus on their attention and careful inspection, will not let everyone down. - Comments: 0

The brick making machine has the characteristics of strong bearing capacity and high production efficiency, can produce high strength, and can finish the production task in a short time, so the enterprise can produce more products and get better benefits.From the above content can be seen brick machine equipment is a pretty good industrial products, can bring people a lot of benefits.and Lontto Machine Machinery Manufacturing Co., Ltd. is a strong strength of the professional production enterprises, in the industry played a leading position, to the vast number of customers to bring superior quality of the brick machine equipment products.The need for a friend to focus on their attention and careful inspection, will not let everyone down. - Comments: 0

The brick making machine has the characteristics of strong bearing capacity and high production efficiency, can produce high strength, and can finish the production task in a short time, so the enterprise can produce more products and get better benefits.From the above content can be seen brick machine equipment is a pretty good industrial products, can bring people a lot of benefits.and Lontto Machine Machinery Manufacturing Co., Ltd. is a strong strength of the professional production enterprises, in the industry played a leading position, to the vast number of customers to bring superior quality of the brick machine equipment products.The need for a friend to focus on their attention and careful inspection, will not let everyone down. - Comments: 0page revision: 0, last edited: 27 Jul 2018 07:16